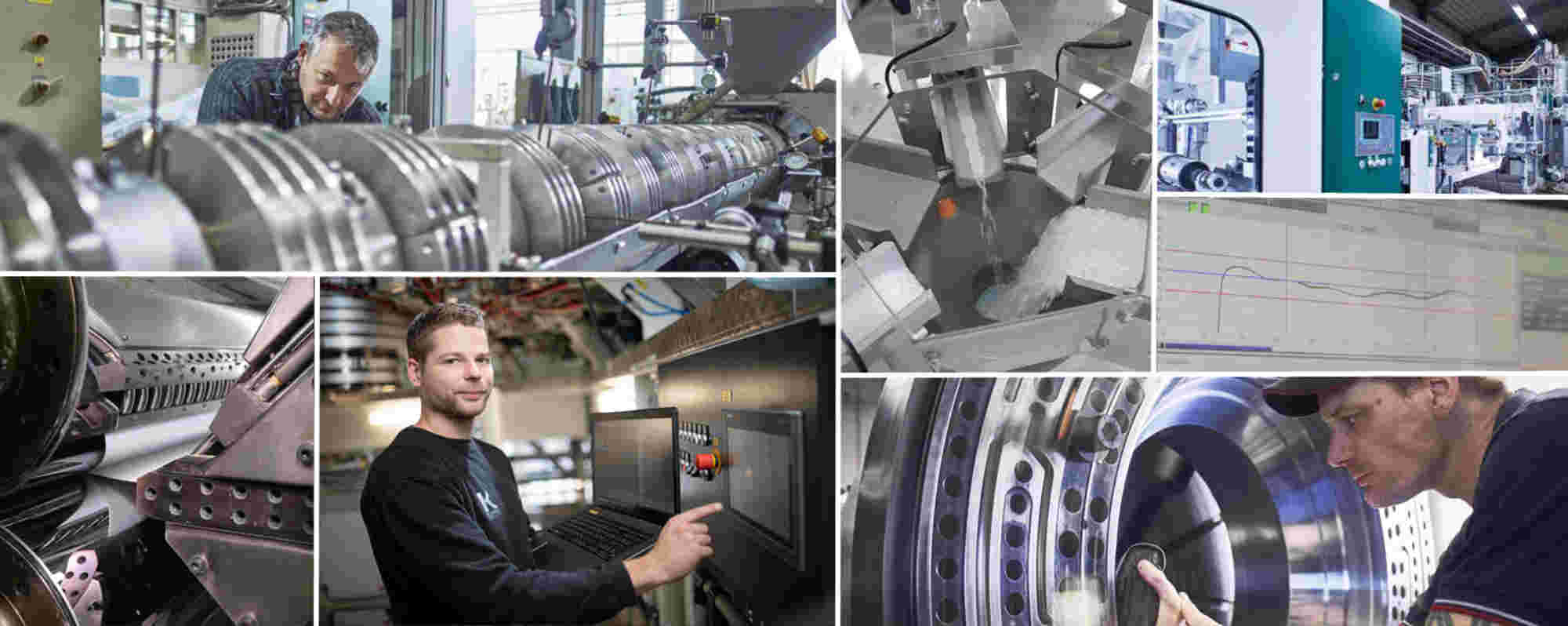

Whether you want to produce a biaxially stretched high-barrier film for fresh meat, an extremely thin laminating film made of HDPE, an EVA film for medical purposes, a dimpled film, a PET film or a foam sheet for the construction industry, we can provide you with the perfect machine solution - including processing know-how.

We are a medium-sized mechanical engineering company specializing in innovative blown film technologies. For more than 30 years we have been finding solutions for complex requirements of our customers. For all types of blown film lines we have developed a modular system of standard components. In addition to a price advantage, this guarantees you above all a maximum of flexibility.

We meet all the requirements of a modern extrusion equipment manufacturer. This is because decades of experience in the design, planning and manufacture of our special machine technology also enable us to optimize the intended end product - from new and improved raw materials to customer-specific products and processes. We work on these with our 230 highly qualified, specialized and experienced employees together with our customers and research institutes and protect their uniqueness via patents and utility models.

We carry out a consistent and complex implementation of all orders in our house. From planning and design to manufacturing and assembly on site. All over the world. Made in Germany. In contrast to many competitors, we even keep areas that are easy to outsource, such as the construction of control cabinets or surface finishing, in-house. We manufacture almost everything ourselves, from subcomponents to complete systems. This is the only way we can guarantee the consistently high quality that our customers and we expect of ourselves - for high volumes as well as for customized special machine solutions.

Innovation, new developments and customized individual solutions are just as much a matter of course for us as the solid and reliable execution of service standards, which naturally have a particularly high level with us. This is because, beyond pure mechanical engineering, we have long also been implementing turnkey plant construction solutions - from structural analysis, planning, design and clarification of the general conditions on site, to the construction of production halls, laboratories and warehouses, to clarification of the question of energy sources and suppliers, logistics, implementation of test series and development of our own recipes.

Each of our systems complies with international CE or country-specific standards, which we work out with the respective safety authorities - including detailed documentation and operating instructions in the local language or a preliminary acceptance test at our plant. This is particularly important for safety-relevant sectors such as the food industry, medicine or pharmaceuticals with the strictest regulations. The same applies to "clean room systems" with special hygienic, environmental and safety aspects and standards, the realization of which is also part of our range of services.

![[Translate to Englisch:]](/fileadmin/_processed_/8/7/csm_kuhne-news-juni_2023_a8f01c7d51.jpg)